Slop-Hopper

Padding top: normal

Padding bottom: normal

Background: white-500

Transvac Systems have developed a range of innovative maintenance equipment specifically designed to enhance the operation of Marine Vacuum Sanitary Systems as installed on a wide variety of vessels and offshore installations operating worldwide.

The Slop Hopper is just one of the products that has been produced as a result of customer demand and a continual development towards the provision of quality equipment to ensure that the Vacuum Sanitary System continues to provide optimal performance for the end user.

Padding top: normal

Padding bottom: normal

Background: white-500

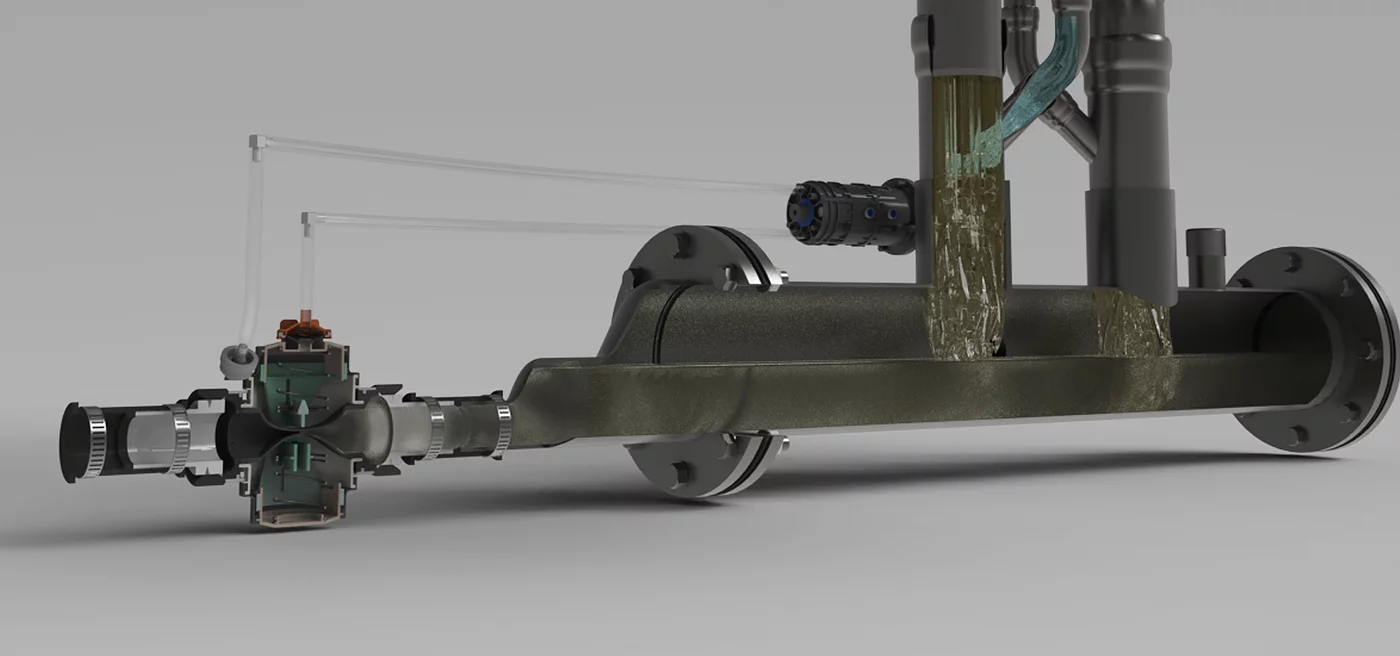

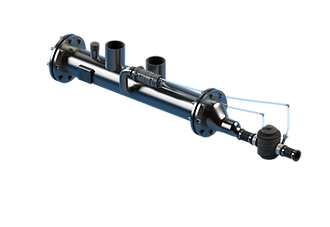

The Transvac “Slop-Hopper” is a large scale vacuum interface valve which can be fitted in-line to collect and black water arisings from Gravity Flush Toilets and Waste Disposal Units fitted to Galley Sinks.The unit is ruggedly designed to handle larger scale debris without fouling. Units are available in either Stainless Steel (AISI 316) or Galvanised Steel.

Padding top: normal

Padding bottom: normal

Background: white-500

How it works:

The gray or black water arisings gravitate to the Slop Hopper collection chamber which is atmospheric. As the level of liquid rises in the chamber to a static head of 80mm a diaphragm in the activator is lifted which, in turn, transfers an operational online vacuum of between -0.35 to -0.6 bar pressure to the discharge valve.

A spring closing mechanism in the discharge valve holds a cylindrical rubber diaphragm shut which effectively isolates the collection chamber from the online vacuum when the unit is in standby mode. When the discharge valve is subjected to vacuum, the closing mechanism is drawn open allowing the contents of the collection chamber to be subjected to vacuum.

Approximately 60 liters of ambient air is admitted into the system during each activation (via pressure differential), which effectively pushes the slug of liquid into the vacuum main towards the collection plant.

After 3 seconds, the activator will close off the supply of the operational vacuum to the discharge valve allowing the closing mechanism to shut the cylindrical rubber diaphragm and isolate the collection chamber from vacuum until the next operation. The activation process will repeat itself as soon as the liquid level in the collection chamber reaches 80mm static head.

Padding top: normal

Padding bottom: normal

Background: white-500

Design features

Part Number: TS-0224-008-01

Collection Chamber: Stainless Steel (AISI 316 or Galvanised Steel

Flange Connections: DN150 PN10

Weight Dry: 55 kg

Internal Volume: 25 Liters

Activator: Evac 900 c/w Flush Memory

Ancillaries: Evac 900 Discharge Valve

Padding top: none

Padding bottom: none

Background: white-500