PiranhaVac

Padding top: normal

Padding bottom: normal

Background: white-500

The PiranhaVac Acid Injection Unit is an innovative maintenance tool which has been specifically designed to effectively de-scale the internal bore of vacuum mains without causing disruption to the operation of the vacuum sanitary system.

The unit is a “cleaning tool” which can be used easily and effectively by the operator to remove the buildup of calcination (on an annual basis) as an onboard maintenance task. In effect, the operator/owner will not require specialist companies to attend the vessel during drydock or emergency periods in order to clean and remove calcination and will gain considerable savings towards maintenance/running costs.

Padding top: normal

Padding bottom: normal

Background: white-500

Design Features:

The PiranhaVac acid dosing unit includes the following standard design features:

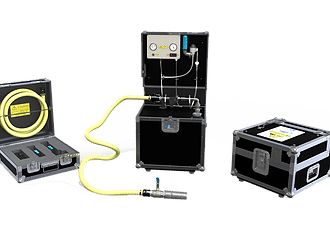

- The unit is portable and self-contained in it’s own heavy duty shipping case which includes an integral wheel set and retractable handle to aid mobility.

- An integral control panel to provide automatic operation of the PiranhaVac unit. The control panel includes a battery gauge and vacuum gauge to monitor the status of the re-chargeable battery and the availability of operational vacuum.

- An integral re-chargeable battery to power the control panel and timer unit. There is no requirement to access power supplies, thereby enabling the user to site and operate the unit in the most tightest of spaces. Note!! A reduced height unit (PiranhaVac Mini) is available for use onboard smaller specialist vessels and yachts.

- A 25 litre chemical tank manufactured in AISI 316 Stainless Steel complete with air vent and 1″ quick release coupler and ball valve arrangement. Note!! Later GEN 2 Piranhavac variants are fitted with polypropylene tanks to increase the longevity

- A solenoid air-valve arrangement complete with silencer to enable chemical to be automatically admitted into the vacuum pipework system during quiet hours.

- A quick release 1″ flexible hose and coupler arrangement to enable the PiranhaVac unit to interface vacuum pipework.

- A side aperture door (Note!! GEN 2 units onwards) fitted to the lid to enable the 1″ PVC chemical interface hose to be connected to the unit with the lid in the closed and locked position. This allows cleaning to take place with the unit securely locked which reduces the operational noise level down to less than 30 dB.

Padding top: normal

Padding bottom: normal

Background: white-500

How It Works:

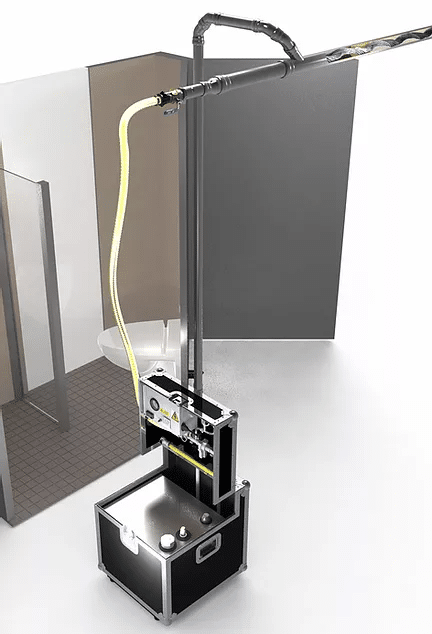

General: The PiranhaVac Acid Injection Unit is connected to the vacuum system via the extreme end of each line. Each unit comprises a Solenoid Valve, Electronic Timer Unit, Battery Power Supply (Re-Chargeable), Chemical Tank and Interface Hose Connections.

Pipework Interface: The chemical solution is usually delivered to vacuum mains by a 1″ PVC hose which is connected to the line using a 1″ Quick Release Camlock Connection and Ball valve arrangement.

Chemical Induction: The integral holding tank is filled with a a chemical solution typically comprising 5 parts water to 1 part Orthophosphoric Acid (Note!! can be variable depending on strength required).

Automatic Operation: The prepared chemical solution is introduced into the sanitary system vacuum main by pressure differential which is created by periodically opening the vacuum main (via the preset solenoid valve arrangement) which, in turn, allows ambient air to be inducted into the manifold creating a venturi effect. The chemical solution is drawn up the manifold where it is mixed with air and forced into the vacuum main in a spiral action where it coats and dissolves the calcinates and effectively removes the linkage from the internal bore.

(Note!! The solenoid valve can be programmed to open at a given interval for a pre-determined time which can be adjusted by the operator if necessary).

Padding top: normal

Padding bottom: normal

Background: white-500

Advantages:

The advantages of the PiranhaVac unit in comparison with other standard techniques are as follows:

- The PiranhaVac unit is one of the only systems available on the market which effectively cleans the vacuum toilet system pipework whilst all of the toilets remain in operation. As a result, the cleaning can take place at any time whilst the vessel is “Under-Way” and carrying a full complement of passengers/crew. The cleaning technique allows the operator to perform the cleaning without any effect or disruption to the vessel’s normal operation.

- The unit is unobtrusive, simple, safe and user friendly. The equipment can be used by the operator as a regular maintenance tool.

- The unit is mobile and can be easily set up by one man. It does not require any monitoring, due to the fact that the timer controller unit maintains automatic dosing on a preset time and quantity. There are no risks of leaks or spillages, due to the fact that the vacuum toilet system remains fully operable whilst the unit is in operation. All liquids are contained in the pipework.

- The cleaning method only uses small amounts of acid which is usually diluted by the time it reaches the sewage treatment plant or vacuum collection unit (Note!! a neutraliser dosing unit can also be supplied to automatically administer neutralising agent to stp’s or collection plants on smaller vessel systems). The action is therefore not detrimental to the biological process of STP’s.

Padding top: none

Padding bottom: none

Background: white-500

Padding top: none

Padding bottom: normal

Background: white-500